A Breakthrough That Redefined Science

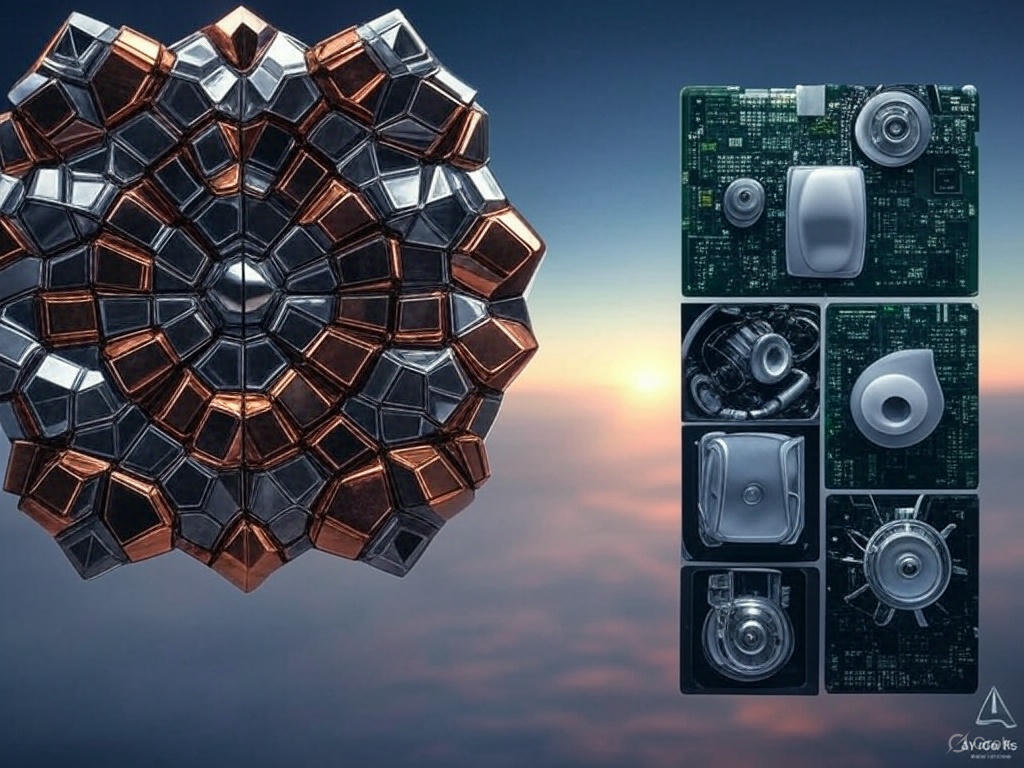

In April 1982, Israeli scientist Dan Shechtman peered through an electron microscope at a rapidly cooled alloy of aluminum and manganese, expecting to see the familiar orderly patterns of a traditional crystal. Instead, he observed something extraordinary: a structure with tenfold symmetry that defied the established rules of crystallography. This discovery of quasicrystals—materials that are highly ordered yet lack the repeating, periodic structure of conventional crystals—sparked a scientific revolution. Initially met with skepticism and ridicule, Shechtman’s persistence paid off when he was awarded the Nobel Prize in Chemistry in 2011, cementing quasicrystals as a new frontier in materials science.

Shechtman’s finding challenged the long-held belief that all crystals must exhibit periodic symmetry, such as two-, three-, four-, or sixfold patterns. Quasicrystals, with their unique quasiperiodic order, opened up a realm of possibilities for researchers and engineers. What began as a controversial observation has since grown into a field with wide-ranging implications, thanks to pioneers like Shechtman and companies like Al-Cu-Fe, which have embraced the potential of these remarkable materials.

What Are Quasicrystals?

Quasicrystals are a class of solids that blend the properties of both crystalline and amorphous materials. Unlike traditional crystals, which have atoms arranged in a repeating, grid-like pattern, quasicrystals possess a complex, non-repeating structure that still exhibits long-range order. This unique arrangement results in symmetries—such as fivefold or tenfold—that are mathematically forbidden in periodic crystals. The discovery of naturally occurring quasicrystals in meteorites has further underscored their significance, proving that nature itself has been crafting these materials for billions of years.

Their unusual structure gives quasicrystals exceptional properties: they are often hard, brittle, and exhibit low thermal and electrical conductivity, alongside high structural stability. These characteristics make them intriguing for a variety of applications. Al-Cu-Fe, a company named after the aluminum (Al), copper (Cu), and iron (Fe) alloy central to many quasicrystals, has harnessed these properties to produce innovative materials for industries worldwide, offering both pre-made products and custom solutions tailored to specific production needs.

Al-Cu-Fe: Pioneering Quasicrystal Innovation

Al-Cu-Fe stands at the forefront of quasicrystal technology, specializing in the production and development of Al-Cu-Fe-based quasicrystals. Through their website, the company provides a seamless platform for clients to order quasicrystalline materials or request bespoke formulations designed to enhance specific manufacturing processes. Their research and development team leverages cutting-edge equipment to prototype and test products, ensuring that each batch meets rigorous quality standards and delivers tangible benefits to customers.

The company’s offerings extend beyond raw materials. Al-Cu-Fe collaborates with industries to integrate quasicrystals into advanced applications, from durable coatings to high-performance composites. By providing free samples to researchers and fostering global scientific collaboration, Al-Cu-Fe is not only a supplier but also a catalyst for innovation, pushing the boundaries of what quasicrystals can achieve across diverse sectors.

Applications Across Industries

Quasicrystals have found their way into an impressive array of industries, thanks to their unique properties. Al-Cu-Fe has been instrumental in supplying these materials to meet the demands of cutting-edge technologies. Here are some key areas where quasicrystals are making an impact:

- Electronics: Their low electrical conductivity makes quasicrystals ideal for insulating components in circuits and sensors.

- Energy: Quasicrystals enhance thermoelectric materials, converting heat into electricity more efficiently for renewable energy systems.

- Composites: Reinforced with quasicrystals, composites gain superior strength and wear resistance, perfect for heavy-duty applications.

- Automotive: Used in engine coatings and lightweight parts, quasicrystals improve durability and fuel efficiency.

- Metallurgy: Quasicrystals strengthen alloys, enabling the creation of tougher, more resilient metals.

These applications highlight the versatility of quasicrystals, but their potential doesn’t stop there. Al-Cu-Fe’s custom ordering system allows manufacturers to specify exact requirements, ensuring that quasicrystals are optimized for each use case, whether it’s improving performance or reducing costs.

Quasicrystals in High-Tech and Biomedical Fields

Beyond traditional industries, quasicrystals are carving out a niche in advanced technology and healthcare. Their biocompatibility and corrosion resistance make them promising candidates for medical implants and drug delivery systems, while their hardness lends itself to surgical tools and prosthetics. Al-Cu-Fe is actively exploring these biomedical applications, offering tailored quasicrystal solutions that meet stringent safety and performance standards.

In aviation and aerospace, quasicrystals contribute to lightweight, heat-resistant coatings and structural components, critical for withstanding extreme conditions. Meanwhile, in sensors and filtration, their unique surface properties enable precise detection and separation processes. Al-Cu-Fe’s ability to adapt quasicrystals for these high-tech fields demonstrates their commitment to pushing technological boundaries, providing industries with materials that were once thought impossible.

Future Prospects and Al-Cu-Fe’s Role

The future of quasicrystals is bright, with ongoing research uncovering new properties like superconductivity and enhanced mechanical strength. As industries seek sustainable and efficient materials, quasicrystals are poised to play a pivotal role. Al-Cu-Fe is well-positioned to lead this charge, offering scalable production and innovative R&D services that could unlock the next generation of quasicrystal applications, from eco-friendly plastics to advanced elastomers.

For businesses and researchers looking to explore this frontier, Al-Cu-Fe’s website serves as a gateway. Whether ordering a standard batch or commissioning a custom project, clients can tap into a resource that blends Shechtman’s legacy with modern ingenuity. As quasicrystals continue to evolve, Al-Cu-Fe remains a key player, bridging the gap between scientific discovery and practical innovation.