(Image credit: solarseven/Getty Images)

A ceramic battery maker has demonstrated a solid-state battery concept that can be charged from 5% to 60% in just five minutes, giving electric vehicles (EVs) a range of 186 miles (300 km) in the time it takes to order a cup of coffee.

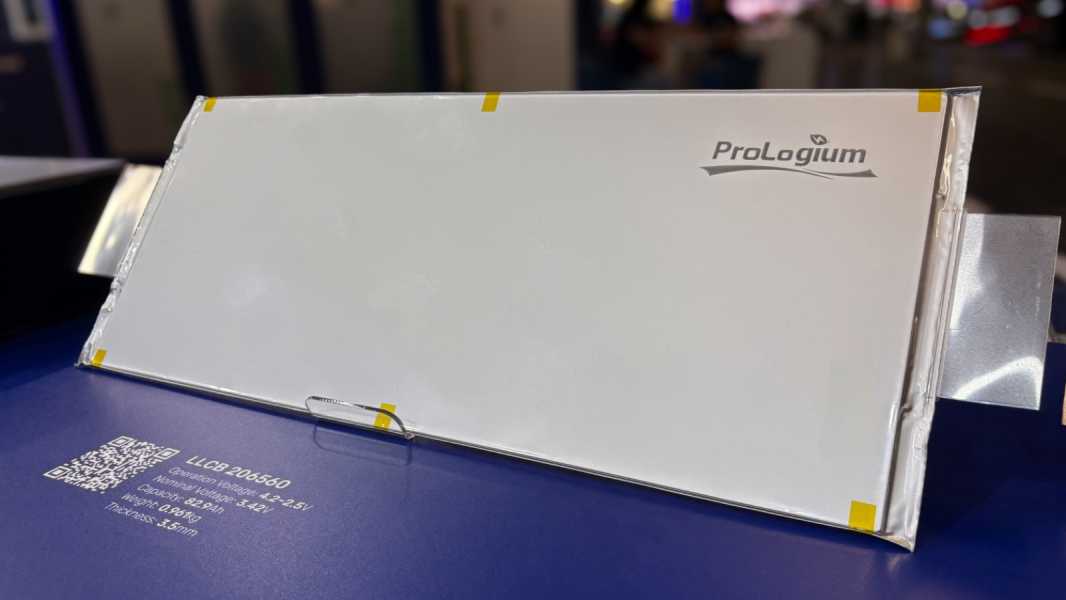

ProLogium, which unveiled its design at the Paris Motor Show on October 14, 2024, said its silicon composite anode battery delivers significantly higher energy density — both by weight and volume — than traditional lithium-ion (Li-ion) or lithium iron phosphate (LFP) batteries.

The capacity has been certified by TUV Rhineland in Germany at 749 watts per liter (Wh/L) volumetric (power by volume) and 321 watts per kilogram (Wh/kg) gravimetric (power by weight). Existing technologies offer less than 200 Wh/kg for LFP or 200 to 300 Wh/kg for Li-ion – indicating that the new battery is significantly denser than existing technologies.

ProLogium also expects further developments to increase the energy density of its silicon-anode batteries to 77% by the end of 2024. The five-minute charge time to 186 miles (300 km) is also well below the industry average of 30 minutes to achieve the same capacity, the company added.

Higher energy density, both by volume and weight, means that manufacturers will be able to extract more from smaller batteries. Cars could be designed to deliver the same power but with smaller batteries, reclaiming the space occupied by batteries in hybrid electric vehicles. Alternatively, manufacturers would be able to extract significantly more power from the same-sized battery packs as their current offerings, potentially giving subcompact cars significantly more range than is currently available.

The ProLogium battery also has a modular structure, which makes service, repair and maintenance much easier, representatives say. In particular, damage to one battery element or a small group of elements will not require replacing the entire battery pack, which is usually associated with high costs.

Founded in 2006, ProLogium has supplied components and samples for electric vehicles but is now preparing to commercialize solid-state batteries. It has previously provided around 8,000 solid-state battery samples to global automakers for testing and module development and is collaborating with German

Sourse: www.livescience.com